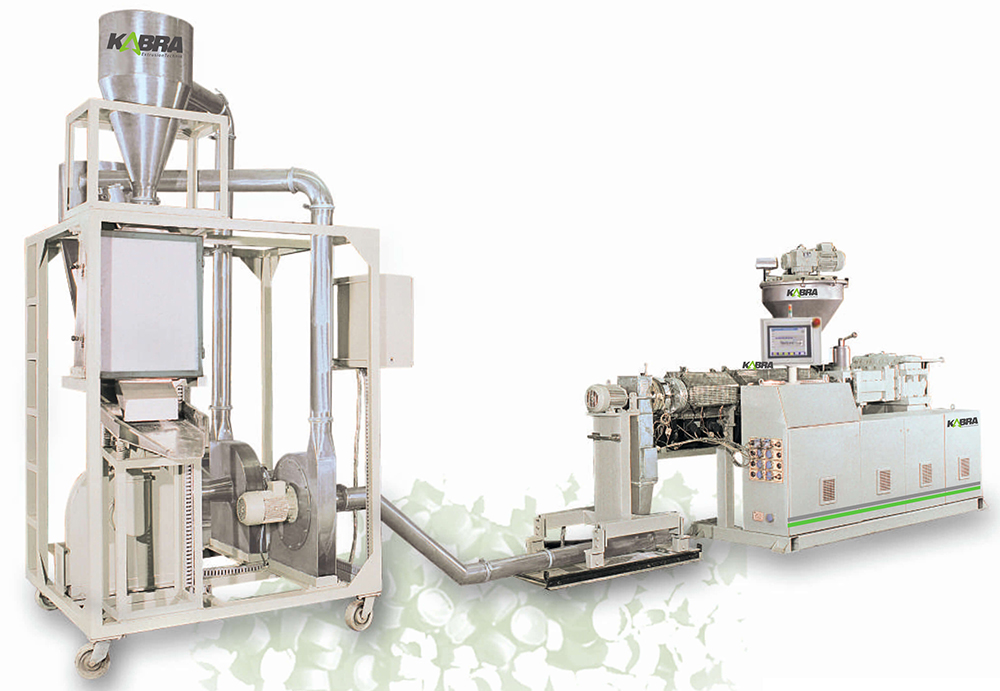

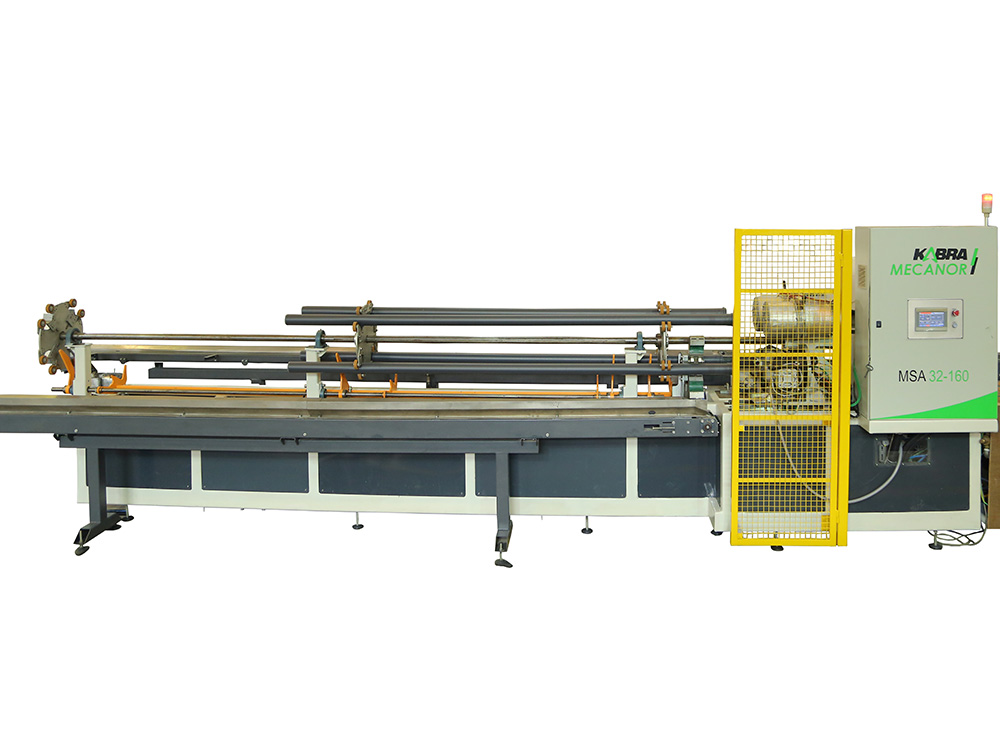

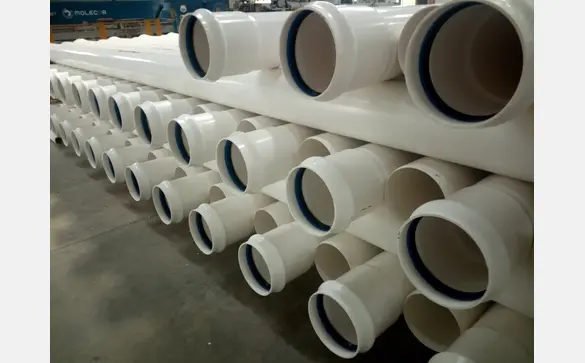

Twin Screw PVC Pipe Extrusion Lines

KET manufactures complete extrusion lines with optimally matched components, sophisticated automation concepts and tailor-made solutions enabling processors to consistently produce high quality end products.

Twin Screw Extruders are crucial for the efficient extrusion of quality PVC pipes. A wide range of products are made on these extruders. They are offered with Screw diameters 52 mm to 168 mm to give output ranges from 120 to 2,000 kgs/hr.

.webp)

.png)

.webp)

(1).jpeg)

(1).jpg)

.png)

(1).jpg)

(1).jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

.webp)

.webp)

.png)