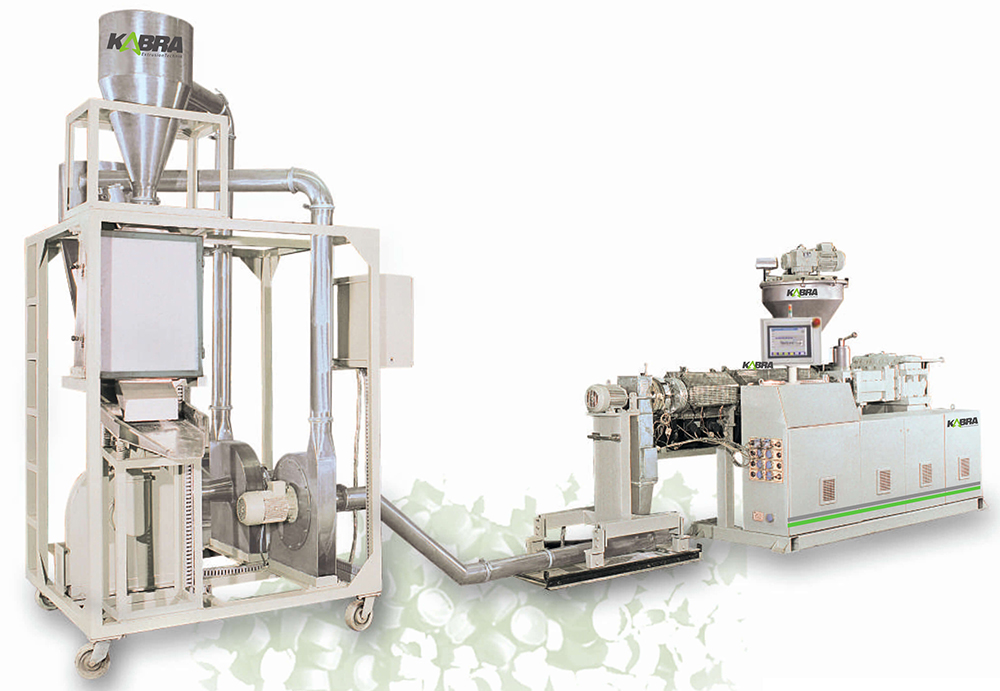

PVC Pelletizing Plant

The Kolsite expertise offered India first Twin- Screw Extruder with high output for manufacturing of PVC Pellets. These extruders give high operational reliability, high pressure build up capability with smaller temperature increase and large degree of freedom in the formulation.

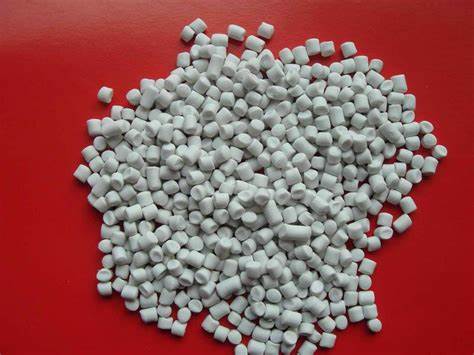

Twin screw extruder offers Electromotive Shear gap adjustment (EMS) for process optimisation and achieving best formulation setting. A cramming unit ensures acceptance of wide range of material and provides positive and continuous feed of poor flowing dry blends. A die face cutter with SS construction arrests contamination and guarantee clean cut with uniform shape and size of pellets. The special Vertical compact Pellet cooler does not allow pellets to sinter.