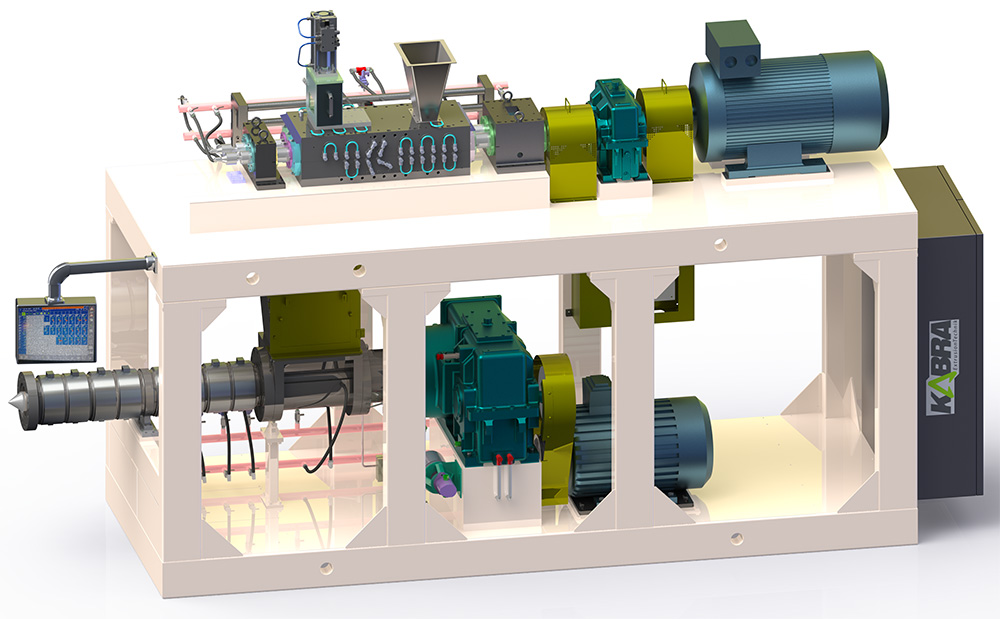

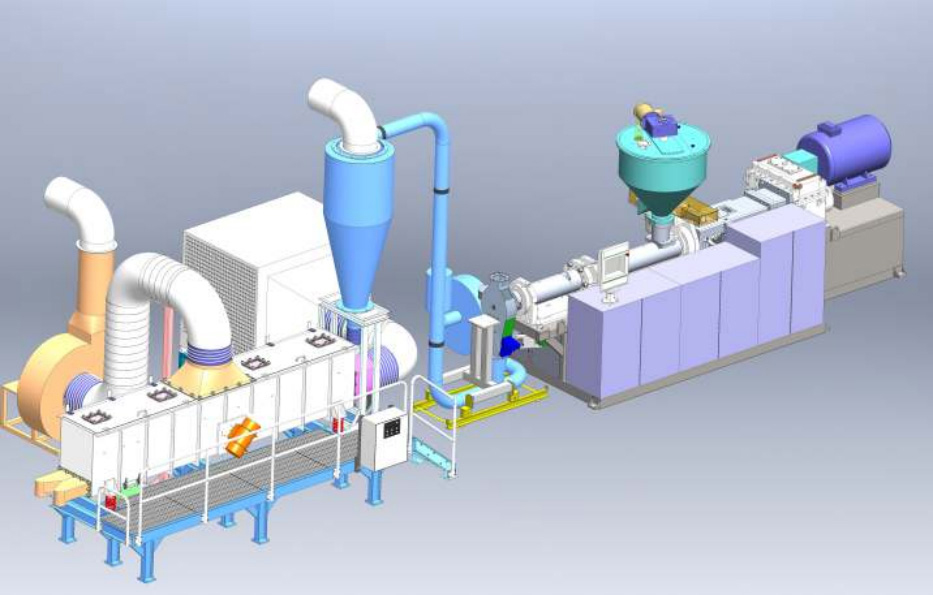

Compounding Lines

Compounding is a process of mixing homogeneously different ingredients of compound formulation, to achieve various properties required for the end application. A typical compounding line consists of Barrel Segments, Screw Elements, Auxiliary equipments post pelletizing, Pelletizing, Close loop Degassing System, Side feeders & Heavy duty gear box.

-resize.jpg)

-resize.jpg)