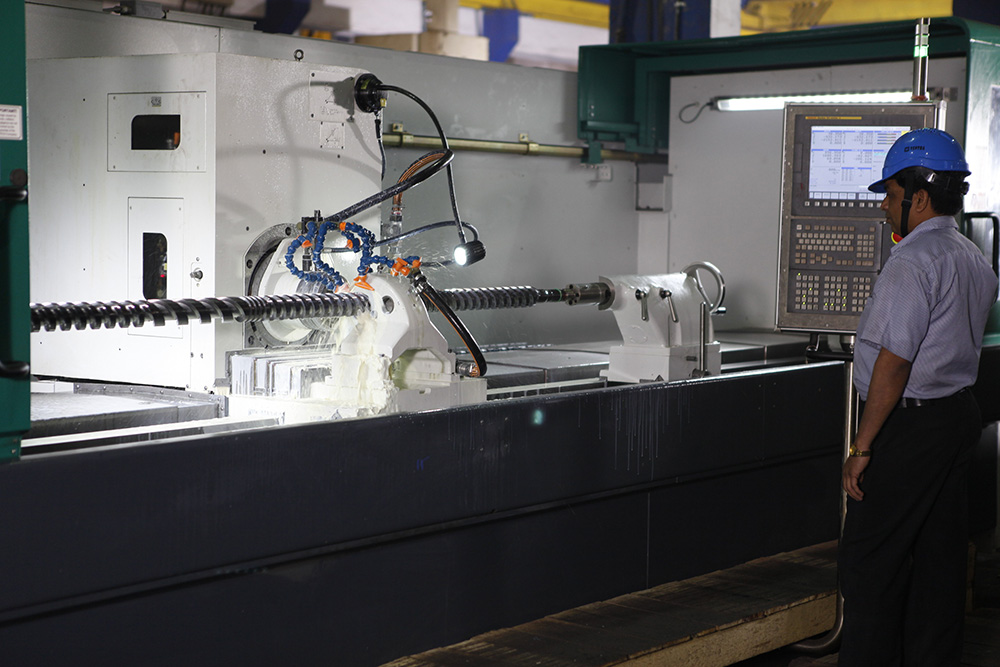

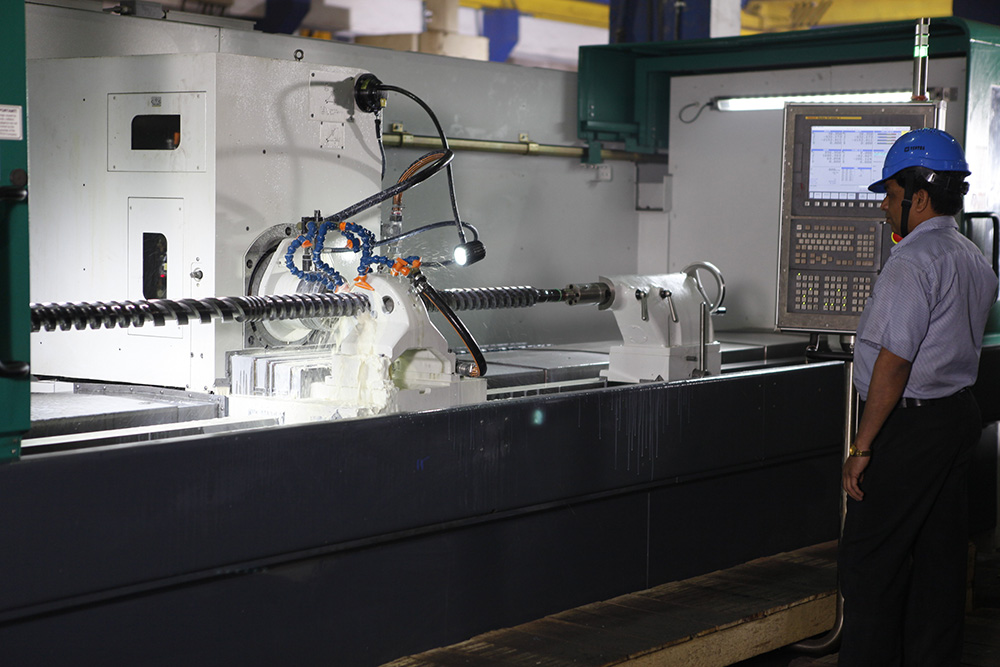

Infrastructure & Manufacturing Capabilities

KABRA Extrusiontechnik has 2 state of the art Manufacturing Facilities with a combined area of about 83820 sq.m. These facilities consist of Administration Buildings, Govt. recognised in-house R&D Unit, Quality Testing Units, Machine Tool Equipment & Paint Shop. KET has one of the largest R&D team in the Plastics Machinery Industry with more than 45 dedicated engineers working in different areas of processing, manufacturing, application development, design, controls and automation.