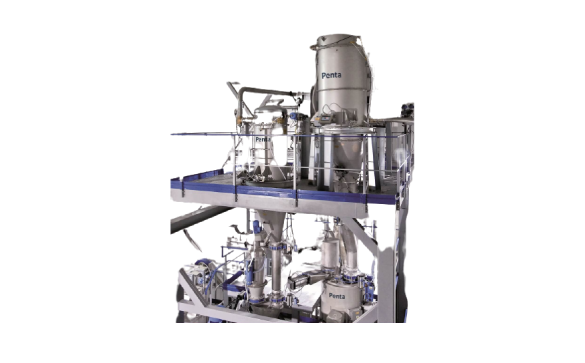

Sheet Extrusion Lines

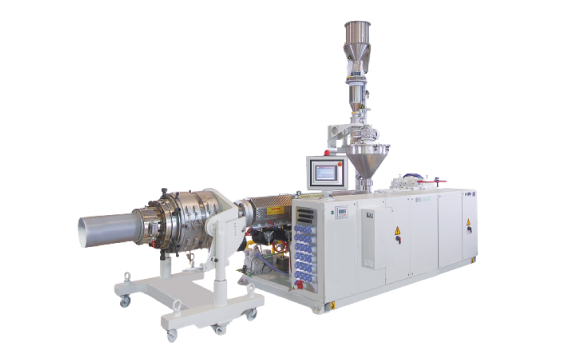

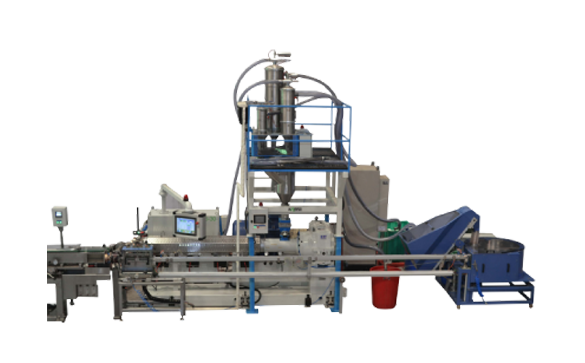

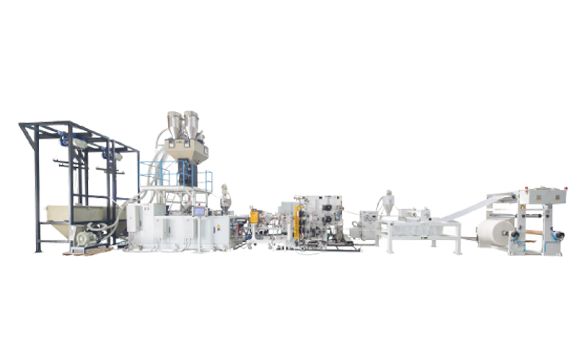

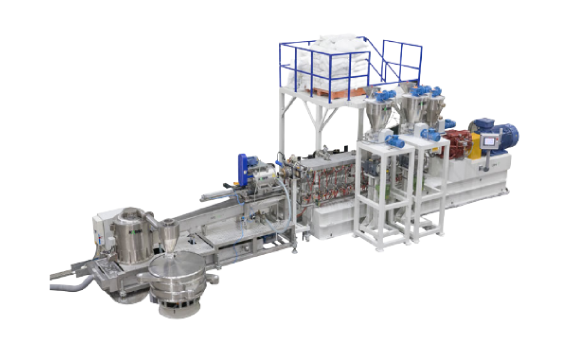

KET offers new generation of high-speed Sheet extrusion lines in collaboration with Battenfeld-Cincinnati, Germany. Plastic sheet requirement for applications like packaging, Liners for white goods, industrial hood packaging and various application of vacuum forming, thermoforming and pressure forming can be manufactured using these state-of-the-art sheet extrusion lines. Wide range of materials like PP, PS, PET, PE etc can be processed using these equipments.

Precision German technology gives processors excellent sheet quality with better thickness control, gloss, haze, glaze and shrinkage properties as compared to available options in the market. The output capacity range is from 300 Kg/Hr to 1200 Kg/Hr.