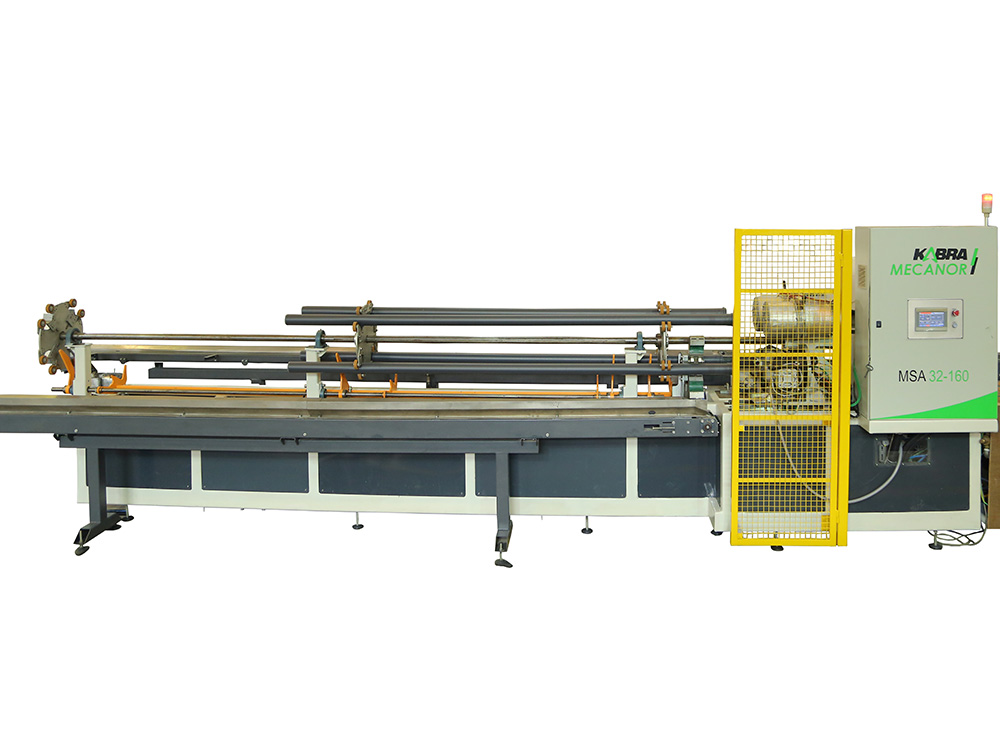

Socketing / Belling Machines

Historically Kabra Kabra Extrusiontechnik is known for state-of-the-art pipe extrusion line for last 5 decades. Belling equipment being manufactured under joint venture with Extron Mecanor is complimenting to the efforts to offer right solution to achieve higher Overall Equipment Effectiveness(OEE).

Unique design of pipe collection and conveying allows to use single belling equipment for twin lane extrusion. Substantial space saving can be achieved.