SAGA Twin Screw Extruders

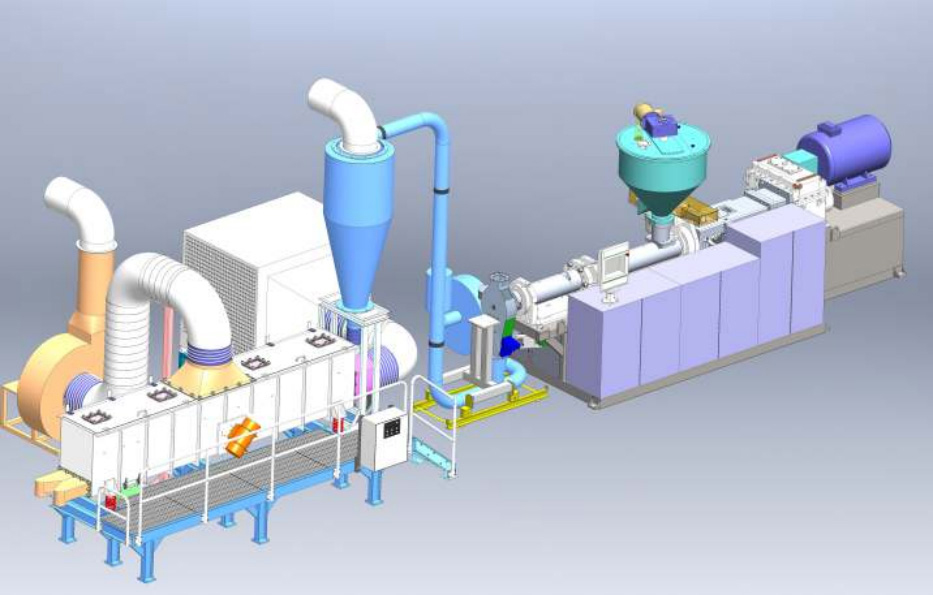

Combination of SAGA and FBC is perfect to achieve highest versatility together with higher compound output. Energy saving offered by the whole system is substantially higher compared to other technology platforms under use.

Combination of SAGA and FBC is perfect to achieve highest versatility together with higher compound output. Energy saving offered by the whole system is substantially higher compared to other technology platforms under use.

This Feature allows operator to adjust shear gap by moving barrel with respect to screws. Desired shear rate rate can be achieved during start - up process as well as in process helping operator to adjust processing conditions, System provides high degree of flexibility to process wide range of both rigid and soft PVC compounds.

Compared to conventional air cooled pellet system, FBC works noise level < 85 dB. Pressure conveying system and breaker fan ensures separation of pellets in case if they stick to each other. Built-in classifire ensures correct final pellet size for packing.

| Type | 2-90-22V SAGA | 2-107-22V SAGA | 2-130-22V SAGA |

|---|---|---|---|

| Output Capability(Kg/Hr) | Upto 700 | Upto 1250 | Upto 1900 |

| Motor Power(Kw) | 75 | 125 | 180 |